Drilling At The Speed Of Sound

24/08/2015 - posted in Bridges, Civils, Geoenvironmental, HBPW News, Value Engineering

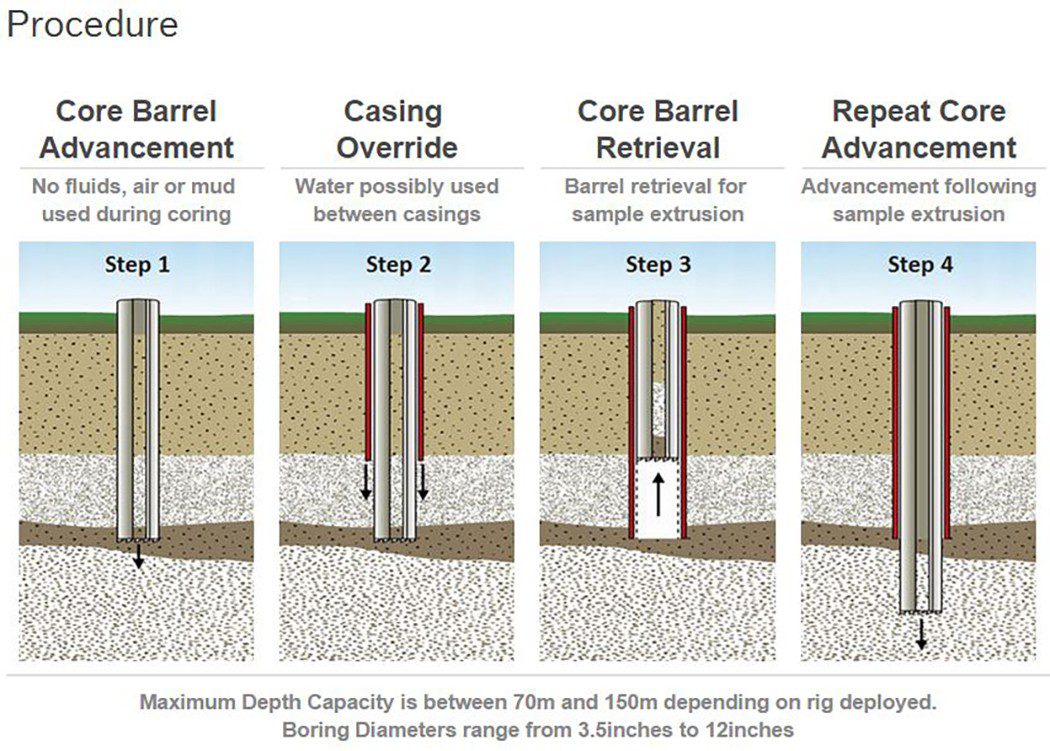

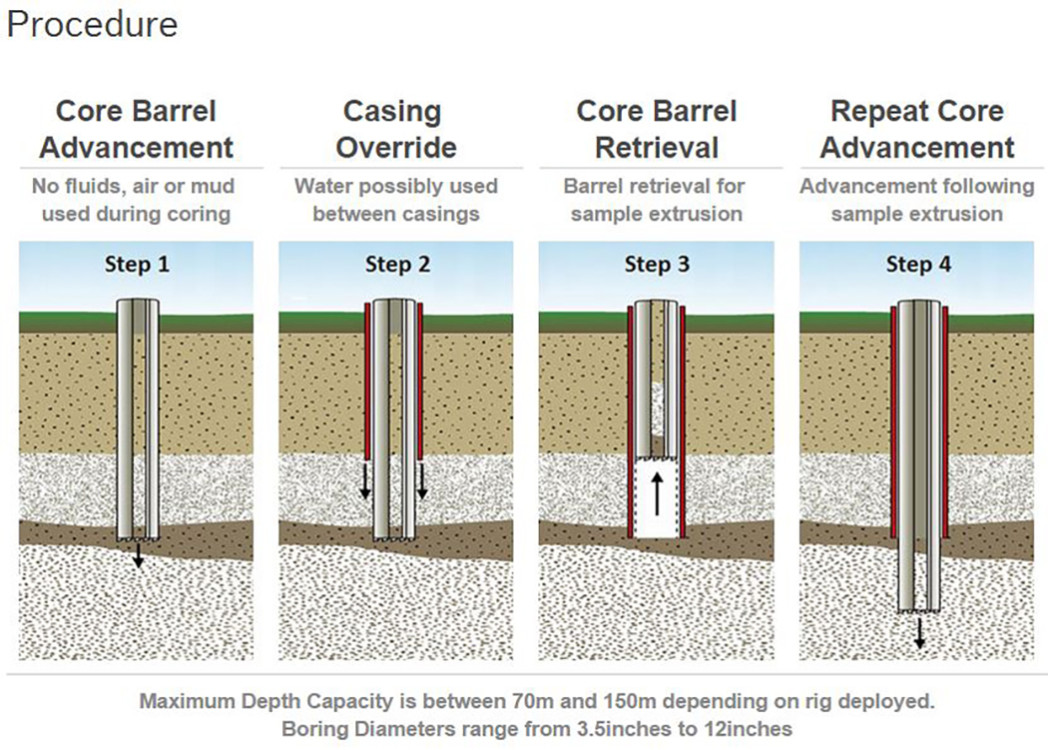

How sonic drilling works

The relatively unknown technique of sonic drilling came to the rescue in Cornwall when a speedy solution to recover good quality samples of weathered rock was required.

HBPW was working on behalf of Carillion Civil Engineering as part of a £27m road scheme which will see the construction of two huge arches across the Red River Valley in Cornwall.

Geoenvironmental engineer, Jay Fox, said: “We needed rock samples but there had been difficulties, previously, whilst drilling at this site, so the project team decided to use a sonic drill from Geosonic of Falkirk in Scotland.

“More conventional techniques such as rotary and percussive drilling, had struggled with the very difficult ground conditions, hence the alternative approach.”

Sonic drilling works by vibrating the drill head up and down at frequencies of up to 150 hertz and, in soft soil, this liquefies a very thin layer, allowing the drill head to pass downwards without affecting the structure of the sample.

“In harder soils, where there is rock and obstructions such as wood and concrete, the sonic action is combined with rotary action to ensure a continuous sample is obtained.

“All concerned were impressed with the speed and quality of the sample recovered, and quite a crowd gathered because few members of the project team had actually seen the technique in action before,” added Jay

Sonic drilling is able to cope with difficult ground conditions and its high speed – up to twice as fast as conventional drilling – more than compensates for the slightly higher costs when compared with other methods. “We will certainly be using it again,” said Jay.

The hardware!